- 5/8/2018

- TWS Tulsa

- 5/8/2018

- TWS Tulsa

- 5/8/2018

- TWS Tulsa

- 4/7/2018

- TWS Jacksonville

- 3/30/2018

- TWS Houston

- 3/29/2018

- TWS Jacksonville

- 2/23/2018

- TWS Jacksonville

- 1/18/2018

- TWS Tulsa

- 1/18/2018

- TWS Tulsa

- 12/18/2017

- TWS Tulsa

- 12/16/2017

- TWS Houston

- 12/16/2017

- TWS Houston

- 12/15/2017

- TWS Tulsa

- 12/2/2017

- TWS Tulsa

- 11/25/2017

- TWS Tulsa

- 11/25/2017

- TWS Tulsa

- 11/3/2017

- TWS Tulsa

- 10/17/2017

- TWS Jacksonville

- 10/13/2017

- TWS Jacksonville

- 10/10/2017

- TWS Jacksonville

Bernard Greene

I’m proud that performed the weld consistently. My biggest challenge in this weld is to overlap your beads more consistently and your travel speed. How I overcome this weld is by not giving up but to correct the minor mistakes that you performed previously. To other students who may read this always remember, each weld you make, try make one that is better than the other and if you keep going you will make it.

Laura King

I’m proud of the work ethic I had when it came down to practicing for Phase 10. After spending a morning working with high frequency, practicing some 6010 SMAW afterwards was a challenge. I learned what to look for in a root pass and how to effectively tie into my tacks. I was surprised by how much working with stainless and Tig helped me when it came time to return to SMAW. I went into with a better understanding of what to look for in any type of root!

Brittany Lewis

This weld is from phase 3; MIG welding. I enjoy each project during this phase because it taught me to have patience and value for myself. To slow down and apply the knowledge gained. My instructor Mr. Paul Pearson; helped me gain more comfortability with welding and his words will stay with me. This weld and my instructor were and will always be my favorite part so far in this journey of mine.

Courtland Harkness

This was a personal project I had done for my stepson Riley who was turning eight with high frequency aluminum drip welding. This type of welding is so much fun and yet so challenging. I adore welding and all the aspects of it especially the muti tasking and technicality of it all, I cannot wait to start my career in welding and am so grateful to Tulsa Welding School and all it’s instructors for everything they teach and how far they push me. I am three weeks away from graduating, I have been in the deans list and have never gotten below a B on any of my projects it’s been a struggle because I have had to work a full time job and provide for my family while attending school and I am so excited to be done and working in this amazing field.

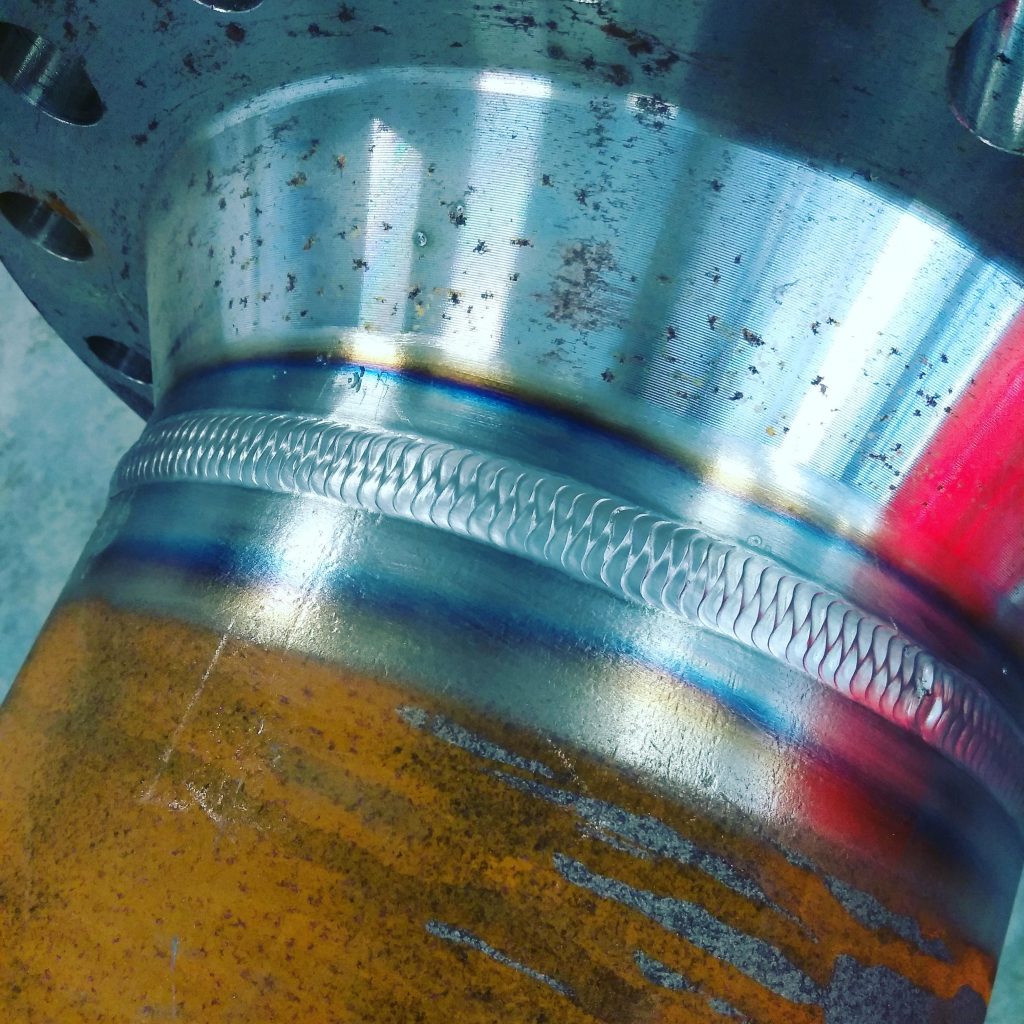

Arturo Montelongo

Tig welding is by far the most fun and I’m proud I got the hang of it fairly quickly. Walking the cup Or the freehand method was a little complicated but with a little patience and good explanation from the instructor I was able to lay good weld beads every time.big thanks to my instructor here at Tulsa Houston cole

Christian Smith

What makes this weld stand out to me is the uniformity amongst the individual beads within the weld as a whole. The challenges overcome were that of travel speed, gun manipulation, as well as consideration for overlap. As progression from one weld to the next one is often reminded of the vast array of parameters that influence the outcome of a weld not only in quality but strength.

Sean Horton

The work I am most proud of is the work I did at he TWS Jacksonville hvac school. I was able to take a display case cooler apart and put it back together as a functional refrigeration cycle display. Fully rewired and added extra components such as schrader valves and a Sight flow indicator. The hardest part for me was probably the brazing all the copper lines due to some of them being in tight spots but it’s also the part I am most proud of since I got them all on the first go with no leaks.

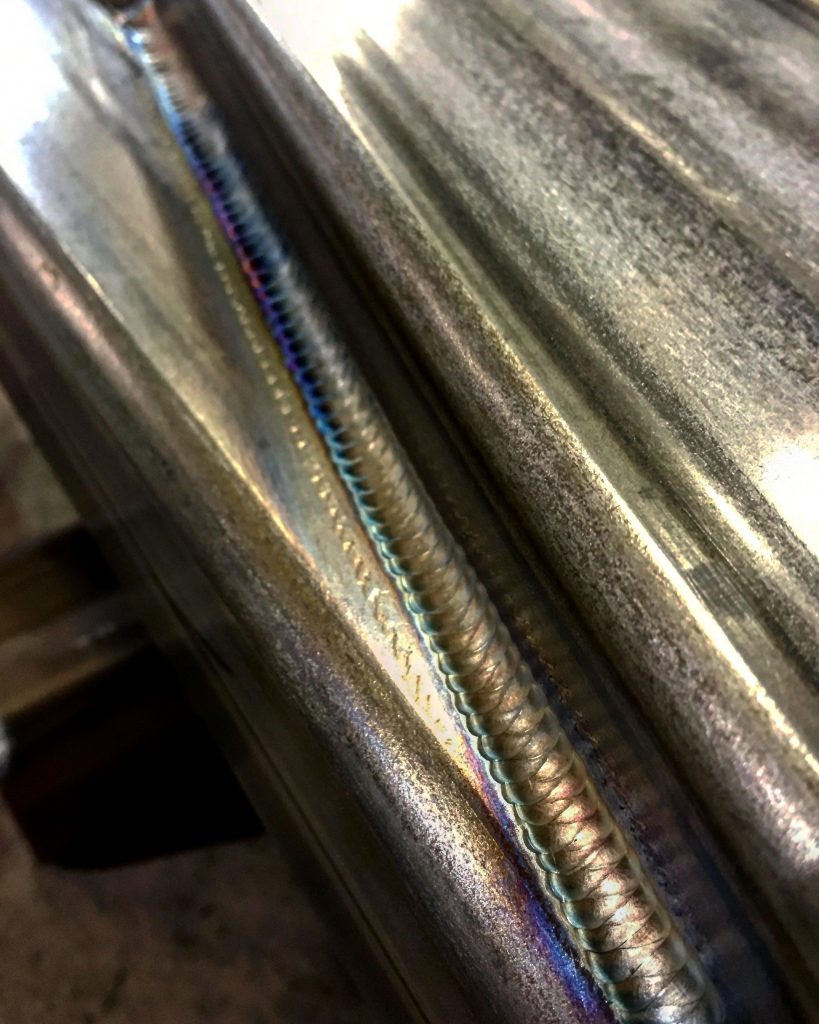

Justin Neal

This was a Tigged out T plate I did in phase 7. Having never welded before school this was a huge hurdle in learning how to “walk” the torch down the pipe to get the desired wave effect. TWS Tulsa is amazing and instructors are helpful and energetic. Just started phase 8….only 3 more then on to the inspectors course!!!!

Jay Green

From working 60 hours a week to a significant hand injust (not welding related), i have faced my fair share of difficulties while attending school. I am proud to say that i am still in school and learning all i can about welding. The fight to the finish will all be worth it after graduation.

Justin Neal

This is was my 6G 6010 root and 7018 3/32 fill and cap final test of phase 5. It was a very difficult phase to get “comfortable” in. I overcame several family hurdles and events this phase to make it past the half way mark! I start phase7 on 12/18 and am excited to start a new internship with a manufacturing plant next month!!!!! Thanks for all the training TWS

Enrique Nieto

I am proud of attending tulsa welding school to teach me how to weld , great instructors great school and great equipment , i am mostly proud of this tig weld came out amazing wouldnt have been made without the help of tulsa welding school. i had trouble walking the cup for a while on tig but to achieve a better weld i stayed after school and got great help from the best instructor jeff pasket!

Cedric Anderson

Hi my name is CedricAnderson I’m proud that I made the right choice to attend Tulsa to father my education. When i first start at Tulsa it was a Challenge for me because, I have never weld before. I also had some great instructors to teach me how to weld. I learned not to never give up on what you are trying to accomplish in life and it take patience to be successful.

James Benninghoff

This was a challenging phase for me at first. I’m proud of the hard work I put into it. I was surprised that I won with all of the other really good welders that I had to compete with. No matter who wins, this school is about being better then you were yesterday. As I watch all of the other welders in my class grow more and more confident day by day, I realize that TWS instructors have done their jobs in teaching us the correct way. Thank you TWS!!!!

– JAMES

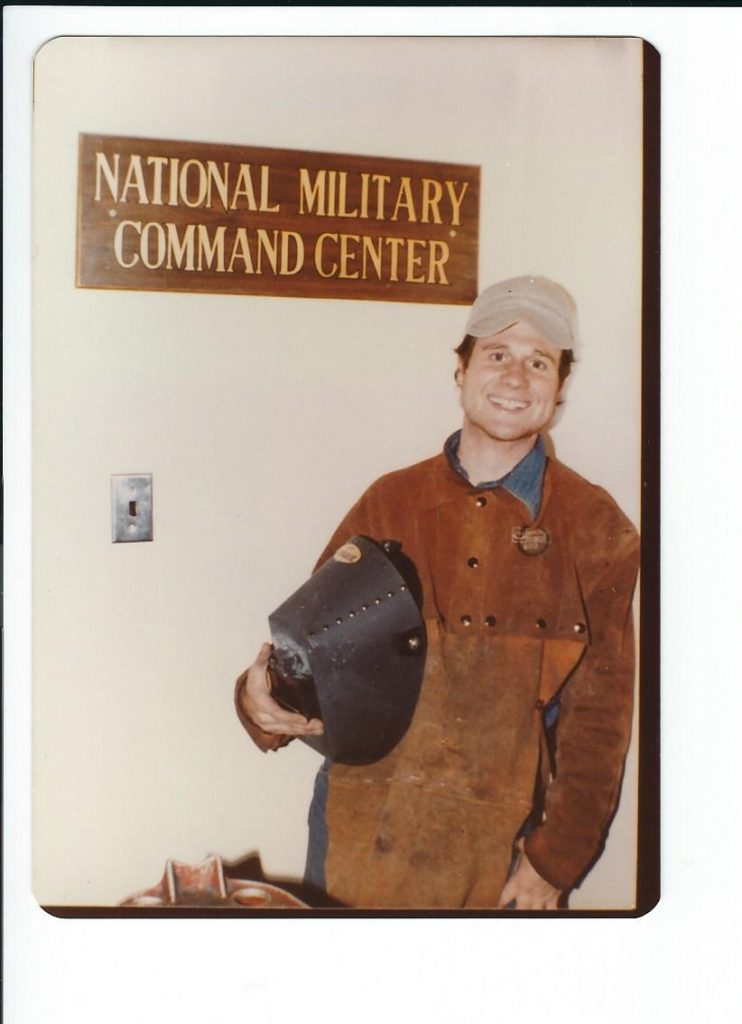

Neal Golbin

Welding some pipe in “the basement” of the Pentagon in 1984…Underground in the Bunker where the Top Brass can run a war..I also had to invent the compact portable smoke removal system (as it did not exist commercially yet). My Tulsa welding instructors were Dick Tyson, Don Apple and Roy Apple. They do not make welders like them anymore. Send me a hat.

Taylor Pippen

I’m most proud of this weld. To me, aluminum was the hardest to weld and not show the heat in the back. I learned how to control the placement of my heat with this particular weld. I kept wanting to put all of the heat on the bottom plate. I eventually figured out that you don’t burn through when you don’t put all of your heat on the bottom. Also, I found a technique that works to make it look correctly. Make an “M” when welding the two together. Great pattern for it. That was the hardest was not walking the cup too!

Austin White

I made this cross for my Grandmother who is now in remission while she was taking chemo treatments fighting breast cancer. This was done in my High School welding class and I have learned to make all kinds of decorative items for friends and family. I am currently a student at TWS.

Jeffrey L. Dedeaux

I’m most proud of Myself and My decision to attend TWS.

I’m a 45 yr old Husband to One Beautiful and extremely patient Woman and Fathe to 7 absolutely wonderful Children.

I was forced out of My Plant job due to MyPhysical Condition/Surgeries. I have been on Disability for almost 6 years now and Its not the Life that I want or Want for My Family.

This is a Life Altering decision that I have made, not just for me but all involved. If I want thing to get better I have got to make a change. Tulsa Welding School seemed like a no-brainer decision.

My Preacher said once; When Life comes to a Dead End at both Forks in the Road, You have got to Pivot!

This is My Pivot and this is just the beginning of a New Chapter in My Story.

Thomas Ellison

This aluminum weld was for me to get in the finish welding side of Diamond Back Airboats, it was what I wanted because it’s the welds that everyone gets to see when they look at their boat. I wanted my work to be noticed so I sat down everyday and practiced through my lunch break, I got my consistency down finally and was promoted to tig welding alot of the finish welds on the boats.

Mike Quinones

I am proud to be a TWS alumni!

Learning to weld has open so many opportunities for me. From welding Coast Guard First Response cutters to custom roll cages for Hybrid Racing new Acura RSX track car. Thank you Tulsa welding for giving me the tools and knowledge of welding to provide me, to find stable career for my family and I.

Bobby Barker

This was my first AWS GMAW structural test a continuous stop and start ever 4 inches. My tie ins are what I’m most proud of its what I struggled with the most while in TWS Jacksonville. I have TWS to thank for the tools they gave me to be able to do what I love.